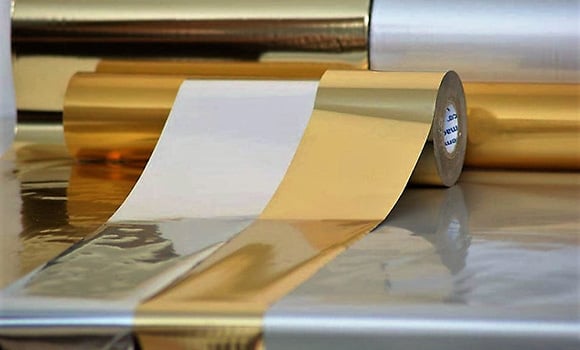

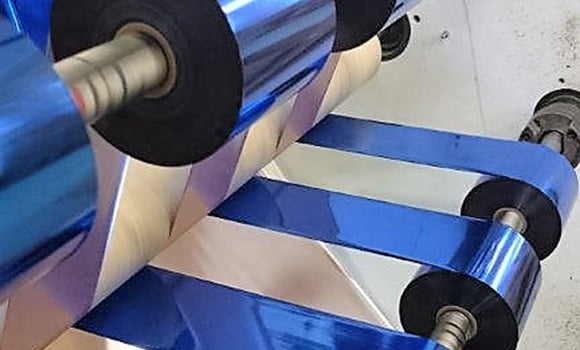

HOT STAMP FOILS

We provide multicolored types of foils. The foils we provide are designed for use in various industries.

We also produce custom made HOT STAMP FOILS- so that you can choose your preferred thickness, width and length, especially suited for your needs.

The foils we provide are designed for use in various industries in various printing methods such as printing heat / cold for all types of surfaces, thermal transfer and adhesive labels. Items of two main product groups are mainly used for marking and decoration technology in the packaging industry.

Lemmaco is a supplier of Thermo Transfer Ribbons, Hot and Cold Stamping Foils, Labels and Self Adhesive Materials, EDEL UV Varnishes, PVA Adhesives and Windows Patching Films. Headquartered in Zsámbék with additional manufacturing, distribution and sales in Austria, Romania, Bulgaria and partner s in Izrael, Czech Republic, Sweden, Norvegien, Denmark, Finland, Serbia, Slowenia, Slovakia.

HISTORY

The first member of Golden Company group: Lemmaco was established in 1999. For today it has become one of the leading hot and cold foil stamping, thermo transfer and self adhesive label supplier in Europe. Items of two main product group are used mostly for marking technology and for decoration in packaging industry. The Golden Company , which has a familiar athmosphere, enlarged its product range with UV varnishes, PVA adhesives, windows patching films and BOPP foil in the course of time. The significant export activity is based by sales team, where colleagues speaks 5 foreign languages and continuously develop their technical knowledge. International presence is also confirmed by regular participation on relevant fairs and exhibitions. The company’s persistent development and reformation is generated by never ending application of technological and technical innovations and using the most up-to- date European Union IMP3rove program tools. As a result of formerly mentioned developments Lemmaco’s customer service quality shows permanent and positive progression. Thanks to flexible production programming and keeping the standards of ISO 9001 and 14001, the company is able to supply its partners on a competitive price level, with high product quality, even from its central site or through its istributors.

AL series

Main Characteristics:

• suitable for both fine line work and larger areas

• excellent adhesion properties on printed, non-printed and varnished

papers

• excellent workability on various stamping machines,

• high heat resistance and high gloss level.

Recommended Applications:

• Folding cartons, cosmetic packaging, liquor and confectionery industry, cigarette packaging, film packs, greeting cards, labels and general graphic applications

Stamping Conditions:

• Vertical machines:: 90°C – 120°C

• Cylinder machines: 130°C – 160°C

AR series

Main Characteristics:

• high speed stamping on all types of stamping machines

• excellent heat and abrasion resistance

• excellent coverage on unprinted, printed and some UV lacquered

surfaces, rough surface paper and board

Recommended Applications:

• Cosmetic cartons, cigarette packages, confectionery packages, wine and spirit boxes,greeting cards, paper-bags, wine and spirit labels, all other uses in graphics and bookbinding industry, PVC coated papers

Stamping Conditions:

• Cylinder machines:120°C – 150°C

• Vertical machines: 100°C – 120°C

BB series

Main Characteristics:

• can be used on wide range of materials

• exceptionally well on bookbinding materials

• high gloss and excellent broad coverage printing effect

• suitable for embossing job

Recommended Applications:

• PVC book cover, plain paper, various rough surface paper and labels, embossed paper, rough surface paper, coated and uncoated papers, book jackets, book binding materials and synthetic leather.

Temperature:

• Vertical and clam-shell machines: 90°C – 130°C

• Cylinder machines: 130°C – 150°C

• Rotary machines: 180°C – 200°C

BB Plus series

Main Characteristics:

• can be used on wide range of materials

• offers very good performance properties also on medium and rough

surfaces

• fine details or large area work

Recommended Applications:

• Coated and uncoated papers, book jackets, and book binding and footwear materials. Applicable on all machine types in footwear and bookbinding sectors.

Temperature:

• Vertical machines: 90°C – 120°C

• Cylinder machines: 120°C – 150°C

BF Plus series

Main Characteristics:

• high speed stamping on all types of stamping machines

• excellent heat and abrasion resistance

• excellent coverage on unprinted, printed and some UV lacquered surfaces

• extremely clean definition with dust free printing

• very high gloss

Recommended Applications:

• good for OPP laminated paper, also for PP, PE and PVC

• cosmetic cartons, cigarette packages, confectionery packages, wine and

spirit boxes, greeting cards, paper-bags, wine and spirit labels, all other

uses in graphics and bookbinding industry

Stamping Conditions:

• Vertical and platen presses: 115°C – 150°C

• Cylinder machines: 135°C – 170°C

• Rotary stamping stations: 170°C – 220°C

BT series

Main Characteristics:

• gives fine definition and solid coverage with consistent release

• high gloss level

• good abrasion and scratch resistance

• suitable for use on nearly all machine types in the graphic industry at high

speed

Recommended Applications:

• Plain paper and board, printed paper and board, embossed paper, dry

paper, rough surface paper, coated paper, PVC labels, PET laminated

papers.

Stamping Conditions:

• Vertical, platen and clam-shell machines: 110°C – 140°C

• Cylinder machine: 140°C – 170°C

• Rotary machines: 200°C – 240°C

BTO series

Main Characteristics:

• Gives fine definition and solid coverage with consistent release

• high gloss level

• good abrasion and scratch resistance

• suitable for use on nearly all machine types in the graphic industry

• high speed

Recommended Applications:

• Plain paper and board, printed paper and board, embossed paper, dry paper, rough surface paper, coated paper, PVC labels, PET laminated papers.

Stamping Conditions:

• Vertical, platen and clam-shell machines: 110°C – 140°C

• Cylinder machine: 140°C – 170°C

• Rotary machines: 200°C – 240°C

CFU series

Main Characteristics:

• free releasing

• clean cutting foil designed for narrow web cold foiling

• fine detail to medium area coverage

• good adhesion after cure,

• good abrasion and scratch resistance

• high transparency to UV light

• high gloss and excellent over-printability with both UV and conventional

inks.

Recommended Applications:

• PP,PE,PET and papers which have non-absorbent surfaces.

Stamping Conditions:

• Roll to Roll cold foiling

COO series

Main Characteristics:

• easy release allowing separation from the stock without snatching

• good clean definition in fine detail applications

• good large area coverage

• excellent adhesion to offset cold foil adhesives

• high abrasion and scratch resistance,

• over printable with most types of printing ink

Recommended Applications:

• coated papers, PE, both smooth and coated card

Stamping Conditions:

• sheet-fed cold offset foil transfer system

GLO series

Main Characteristics:

• gives fine definition with consistent release

• high gloss level

• good abrasion and scratch resistance

Recommended Applications:

• Plain paper and board, printed paper and board, embossed paper, dry

paper, coated paper, Art paper, simili paper, fancy paper

Stamping Conditions:

• Vertical, platen and clam-shell machines: 105°C – 135°C

• Cylinder machine: 130°C – 160°C

GLS series

Main Characteristics:

• gives fine definition with consistent release

• high gloss level

• good abrasion and scratch resistance

Recommended Applications:

• Plain paper and board, printed paper and board, embossed paper, dry paper, coated paper, Art paper, simili paper, fancy paper

Stamping Conditions:

• Vertical, platen and clam-shell machines: 105°C – 135°C

• Cylinder machine: 130°C – 160°C

KF series

Main Characteristics:

• high operating speed

• fine definition with consistent release

• good halftone effects

Recommended Applications:

• applicable on suitable modified reel-to- reel label presses

• applicable on a wide range of non-absorbent surface papers and all types of label stock. PP, PE label films: 2.5-5.0 g/m 2 , non-absorbent surface

papers: 5.0-7.0 g/m 2

• ensure the hardness of nip roller is between 85 to 90 shore A hardness

Stamping Conditions:

• wet process: 50-90 m/min with higher than 180 watts/cm (450 watts/inch) UV lamp

KFO series

Main Characteristics:

• overprintable with both conventional and most of UV inks

• fine definition with consistent release

• high gloss on board coverage

• special-purpose foil for cold foiling without die

Recommended Applications:

• applicable on suitable modified reel-to- reel label presses

• applicable on a wide range of non-absorbent surface papers and all types of label stock. PP, PE, label films: 3.0-6.0 g/m², non-absorbent surface

papers: 6.0-8.0 g/m².

Stamping Conditions:

• wet process: 40-120 m/min with higher than 180 watts/cm (450 watts/inch) UV lamp

KOO series

Main Characteristics:

• for the sheet-fed offset cold foil stamping applications by conventional

adhesive

• holographic effect

• fine definition with easy release

• high gloss on board coverage

• good over printability with conventional inks (previous tests

recommended)

Recommended Applications:

• applicable on a wide range of coated and uncoated paper and carton. and plastic materials (PE, PP, PET) or other substrates with non-absorbent surfaces. Applicable on the offset presses with cold foil module

Stamping Conditions:

• high operating speed over 8000 sheets/hr up to 10000 are possible

LK series

Main Characteristics:

• gives fine definition with consistent release

• good abrasion and scratch resistance

• versatile foil with good adhesion on most of coated or UV varnished papers and OPP lamination papers

Recommended Applications:

• PET/OPP laminated papers, UV varnished paper, plain paper and board, printed paper and other various papers

• recommended for cosmetic paper boxes, wine boxes and labels, greeting cards, PET lamination paper, ink printed paper and unprinted paper, UV

varnished paper, various stick (label) and other papers

Stamping Conditions:

• Up-down, vertical, platen and Clamshell stamping machine: 90°C – 120°C

• Cylinder machines: 120°C – 150°C

• Rotary machines:180°C – 230°C

PF series

Main Characteristics:

• ideally suited for low temperature, low pressure applications

• offering easy stripping to produce clean and sharp impressions

• formulated for fine to medium coverage

• gives sharp definition and good heat resistance

• suitable for high speed stamping, and is an excellent foil for rotary label

applications

• over stamp most coatings and inks

Recommended Applications:

• PSA labels, dry stocks, coated and uncoated paper, variety of inks and coatings, film. The PF series is a versatile foil designed for coated and uncoated stocks.

Stamping Conditions:

• Vertical: 90°C – 135°C

• Cylinder: 180°C – 200°C

PL series

Main Characteristics:

• suitable for stamping on all types of stamping machines

• excellent heat and abrasion resistance

• extremely clean definition with dust free printing

• very high gloss.

Recommended Applications:

• cosmetic cartons, cigarette packages, confectionery packages, wine and spirit boxes, greeting cards, plastic and paper-bags, wine and spirit labels, all other uses in graphics and bookbinding industry

• good for OPP laminated paper, also for OPP, PET, PVC.

• excellent coverage on unprinted, printed and UV lacquered surfaces

Stamping Conditions:

• Platen machines :100°C – 140°C

• Cylinder machines: 120°C – 160°C

• Rotary machines: 160°C – 205°C

PS series

Main Characteristics:

• improved working range

• high working speed

Recommended Applications:

• Recommended substrates are: cigarette packages,

labels, paperbacks, greeting cards, cartons, boxes. The PS series for UV

varnishes, rough surfaces, large area or large format stamping

Stamping Conditions:

• Platen machines :110°C – 140°C

• Cylinder machines: 135°C – 160°C

• Rotary machines: 150°C – 200°C

SL series

Main Characteristics:

• gives fine definition with consistent release

• good abrasion and scratch resistance

• good adhesion properties on OPP laminates

• suitable for use on nearly all machine types in the graphic industry

Recommended Applications:

• plain paper and board, printed paper and board, embossed paper, dry paper, rough surface paper, coated paper, PVC labels, OPP film laminated

paper, PP synthetic paper

• printed unprinted and lacquered surfaces

Stamping Conditions:

• Vertical, platen and clam-shell machines: 105°C – 135°C

• Cylinder machine: 130°C – 160°C

• Rotary machines: 200°C – 240°C